CHINAPLAS 2025 is set to take center stage! From April 15–18, the global plastics and rubber industry will converge at the Shenzhen World Convention & Exhibition Center for this premier event. As a leading trade show, CHINAPLAS brings together 4,000+ exhibitors from 40 countries, spanning 380,000 sqm of exhibition space — including 9 dedicated international pavilions.

Alongside numerous international exhibitors, Dekuma will meet you at Booth 8B41 and showcase their advanced rubber injection molding machines, specifically RV300F and RV200F. Whether you are looking for new material breakthroughs or exploring the future of smart manufacturing, CHINAPLAS 2025 will open the door to unlimited possibilities!

What is CHINAPLAS 2025?

CHINAPLAS is an annual international event for the plastics and rubber industry and one of the largest and most influential industry exhibitions in Asia. CHINAPLAS 2025 will further expand its scale, presenting a richer variety of innovative technologies and solutions for the global industry players.

Detailed information about CHINAPLAS 2025 is listed below:

- Exhibition Hours

- April 15-18, 2025 (09:00-17:00)

Note: CHINAPLAS is a specialized trade show open only to industry professionals

- Exhibition Venue

- World Exhibition & Convention Center (Bao’an), Shenzhen, China (all 19 halls)

- Exhibition Scale

- Exhibition area: 380,000 square meters

- Exhibitors: over 4,000 from 40 countries and regions

- International pavilions: including Germany, Austria, Italy, UK, France, Switzerland, Japan, and the USA

- Exhibition Area Setting

- Machinery & Equipment Zone: occupy 70% of the exhibition area, showcasing cutting-edge technologies in injection molding, extrusion, and blow molding

- Material Zone: presenting innovative material solutions

- Other zones: intelligent manufacturing, sustainable development, and other thematic zones

- Concurrent Events

- 3rd SciXplore Forum

- Tech Talk

- innoGreen Hub

- 6th Plastics Recycling & Circular Economy Conference & Showcase

- CPS+ eMarketplace

- Exhibition Profile

CHINAPLAS 2025 is not only a platform for global plastics and rubber innovations but also promotes in-depth exchanges of cutting-edge technologies and sustainable development practices through high-end forums and industry dialogues.

Here, exhibitors and professional visitors can explore the latest products and participate in technical seminars to discuss industry trends, green transformation, and future opportunities, injecting new momentum for industrial upgrading.

What to Expect from Dekuma at CHINAPLAS 2025

Established in 2004 as a wholly owned subsidiary of the Hong Kong publicly listed Cosmos Machinery Enterprises Limited, Dekuma specializes in the research, development, and production of rubber injection molding equipment. With innovative control systems and superior mechanical designs, Dekuma delivers rubber injection molding machines for high reliability and stability.

Additionally, their experienced technical team enables them to develop equipment tackling complex rubber molding processes to address the requirements of diverse industries, such as automotive and power industries. Quality products and profound experience help Dekuma become a key player in proceeding with rubber molding technologies.

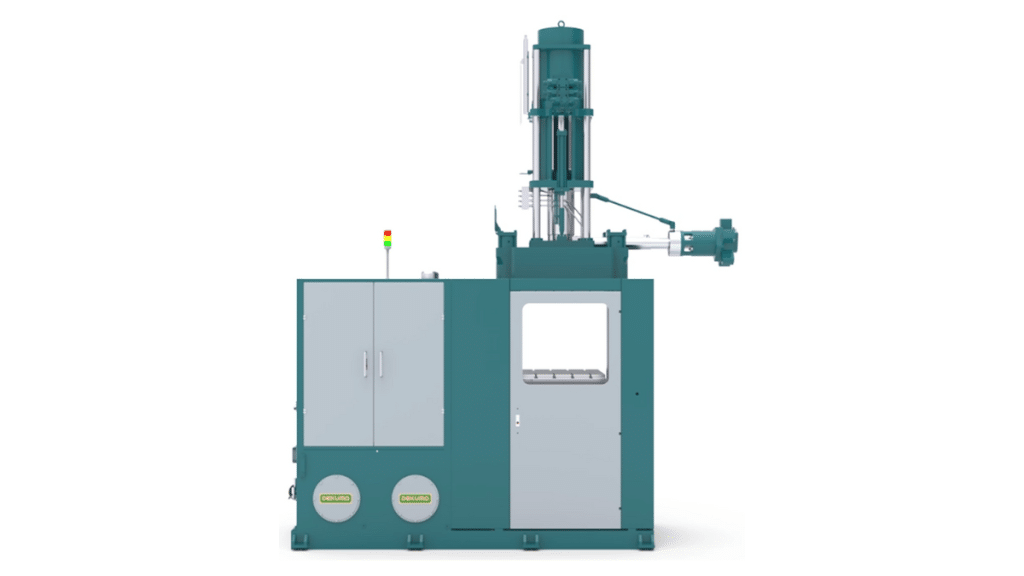

RV Series Machines from Dekuma

At CHINAPLAS 2025, Dekuma will show its RV Series Rubber Injection Molding Machines, including the RV300F and RV200F models. Both of them meet the demand for energy-efficient and precise molding solutions.

The RV300F has a clamping force of 3000 kN for larger molds and complex geometries to produce high-performance automotive rubber parts. The RV200F (a clamping force of 2000 kN) offers flexibility for manufacturers preferring medium-sized parts.

Both have injection units for steady material flow and lower waste, which backs the industry’s move towards sustainable manufacturing practices. With such machines at CHINAPLAS 2025, Dekuma proves it delivers solutions for current tech and environmental trends.

Features & Benefits of Dekuma’s Rubber Injection Molding Machines

Dekuma’s RV300F and RV200F rubber injection molding machines precisely satisfy the demands of manufacturing. Their features include:

- Advanced design: Dekuma adopts the plasticization and injection system optimized by German experts, and its innovative screw design can process ultra-high hardness materials.

- System performance & efficiency: Featuring premium imported double-layer thermal insulation plates, the RV system reduces energy consumption by 40% versus standard configurations, delivering measurable reductions in lifetime energy expenditures.

- Sealing: The dual-seal clamping cylinder maintains sealing reliability and avoids oil leakage.

- Reliability: The American high-pressure pump and the German hydraulic valve work together to guarantee stability and reliability during continuous production.

- Precision & control: The industry-leading electronic ruler ensures ± 0.05% positional accuracy across all injection and clamping movements.

- Material adaptability: The Dekuma RV series can process various materials, including NR, NBR, EPDM, and isobutylene isoprene rubber, ensuring broad compatibility.

- Wide application: Dekuma RV rubber injection molding machines produce complex high-precision components, like seals, cable connectors, and rubber vibration absorber cylinder cushions. They can satisfy the manufacturing demands of automotive, electric power, and civil industries.

Machine Specifications Comparison between RV300F and RV200F

| Specification | RV300F | RV200F |

| Clamping Force | 3,000 kN | 2,000 kN |

| Injection Volume | 3,000 cc | 2,000 cc |

| Heating Plate Size | 650 mm x 650 mm | 500 mm x 550 mm |

| Injection Pressure | 1750 bar | 1750 bar |

| Machine Dimensions (LxWxH) | 3.9 m x 2.4 m x 4.1m | 3.7 m x 2.2 m x 3.7m |

| Total Weight | 8.5 tons | 6.5 tons |

Visit Dekuma at CHINAPLAS 2025

CHINAPLAS 2025 is an industry event you don’t want to miss! Dekuma invites you to visit Booth 8B41 to experience our high-performance rubber injection molding technology.

Known for high injection pressures, excellent sealing, and ultra-stable hydraulics, the Dekuma RV series is designed for demanding applications such as automotive and power industries.

On-site, you will:

✓ Meet one-on-one for technical interaction

✓ Get customized solutions

✓ Learn how Dekuma equipment can improve your productivity

Schedule a visit today to open up new opportunities for collaboration! For more, visit their website.