The rapid evolution of 3D printing technology has significantly impacted industries such as manufacturing, healthcare, and aerospace. Central to this advancement is the development of innovative materials that enhance the capabilities and applications of additive manufacturing. As we approach 2025, several emerging 3D printing materials are poised to further revolutionize 3D printing industry.

High-Performance Engineering Plastics

Advancements in engineering plastics have led to materials with superior mechanical properties and thermal resistance. These materials broaden the scope of 3D printing applications.

- High Transparency Resin (e.g., Raise3D V1 Resin): This resin offers ease of printing and results in semi-transparent parts with a slight blue tint, making it ideal for optical components and prototypes requiring clarity.

- Ultracur3D® RG 1100 B: A high-strength, polyurethane-based engineering-grade resin, Ultracur3D® RG 1100 B exhibits a high heat deflection temperature (HDT of 100°C), excellent chemical resistance, and long-term UV stability. These properties make it suitable for demanding applications such as automotive connectors, exterior covers, and housings.

- Ultracur3D® RG 3280: This ceramic-filled resin boasts exceptional stiffness, with a Young’s modulus around 10 GPa, and a heat deflection temperature exceeding 280°C. Its high rigidity and thermal resistance make it suitable for molds, tools, and high-precision testing applications.

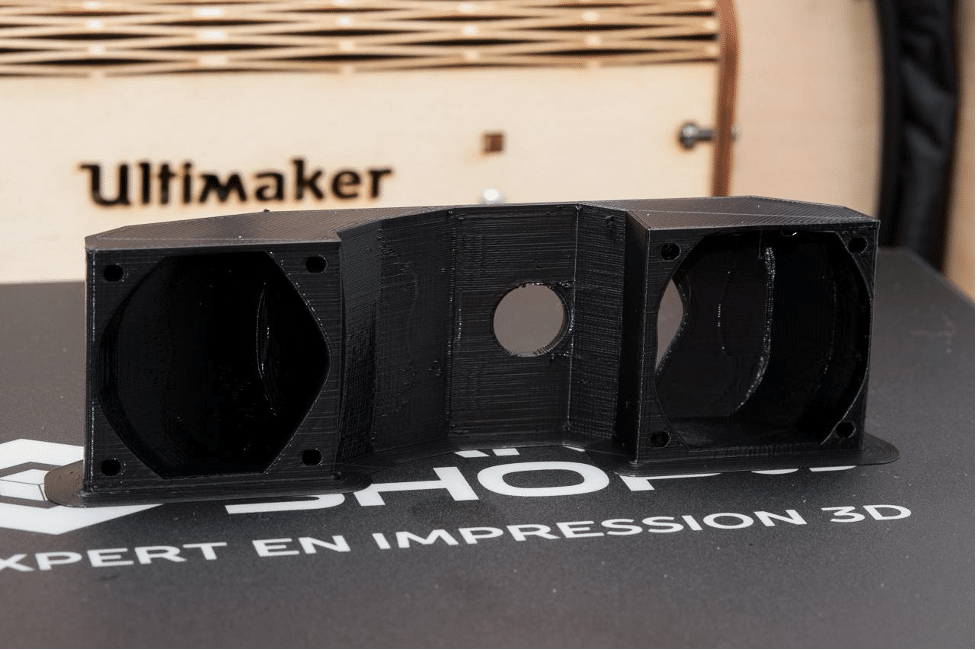

Composites: Combining Lightweight and High Performance

The integration of reinforcing fibers into polymers has resulted in composites that offer a balance between weight reduction and enhanced mechanical properties.

- Carbon Fiber Reinforced Polymers: Materials like Farsoon’s FS6130CF-F are designed for high-demand industries such as automotive and aerospace. This carbon-fiber-reinforced PA6 material provides high tensile strength, heat resistance, and rigidity, making it ideal for components that require durability under stress.

- Metal Matrix Composites: By combining metal filaments with plastic matrices, these composites achieve a balance between metal-like aesthetics and the ease of processing associated with polymers. Applications include decorative items and functional parts where both appearance and performance are important.

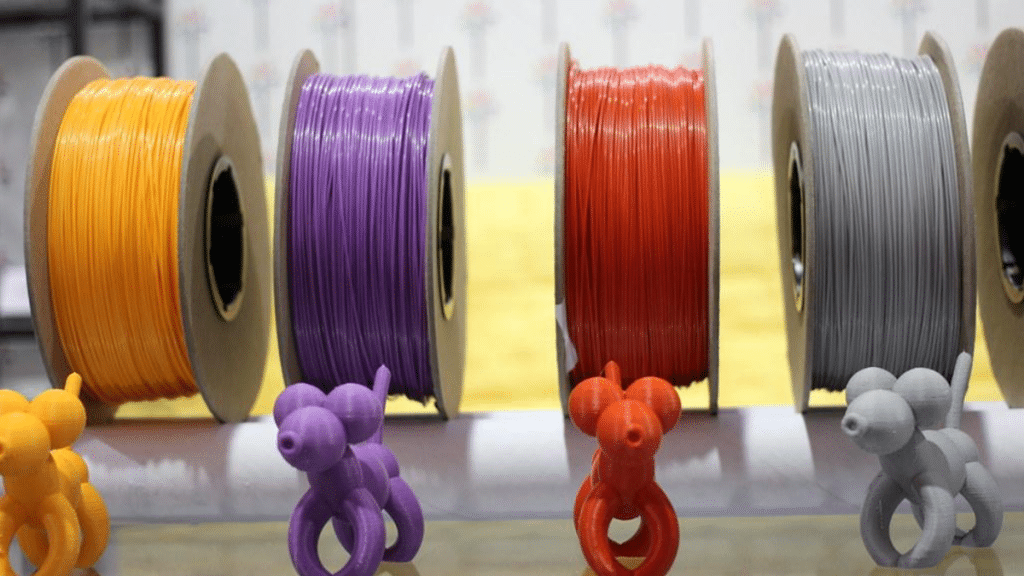

Bio-Based Materials: Sustainability Meets Creativity

The push towards sustainability has led to the development of bio-based materials that are both eco-friendly and versatile.

- PLA and Organic Blends: Polylactic acid (PLA) combined with organic materials such as wood fibers or coffee grounds results in biodegradable filaments ideal for art, design, and low-stress applications. These materials offer unique aesthetic qualities while reducing environmental impact.

The demand for sustainable 3D printing materials is expected to rise in 2025, particularly in industries focused on eco-friendly design and packaging solutions.

High-Temperature Alloys: Innovation for Extreme Environments

Industries operating under extreme conditions require materials that maintain integrity under high temperatures and stress.

- ABD-1000AM Nickel-Based Alloy: Developed for applications in aerospace, automotive, and defense, this alloy withstands temperatures exceeding 1000°C while maintaining excellent mechanical properties. Its resilience makes it suitable for critical components exposed to harsh environments.

The utilization of high-temperature alloys in 3D printing is anticipated to grow as industries seek materials capable of performing under extreme conditions.

Conductive Materials: Integrating Electronics with 3D Printing

The convergence of electronics and 3D printing has led to the development of conductive materials that enable the fabrication of functional electronic components.

- Conductive PLA or ABS with Carbon Particles: These materials allow for the printing of low-current electronic components such as sensors and wearable devices, facilitating the integration of electronic functionality directly into 3D-printed objects.

As the demand for customized electronic devices grows, conductive 3D printing materials are set to play a significant role in the electronics manufacturing sector.

TCT Asia 2025: Showcasing the Future of 3D Printing Materials

TCT Asia 2025 is poised to be a premier event highlighting the latest innovations in 3D printing materials. Attendees can expect to see cutting-edge developments in high-performance resins, composites, bio-based filaments, and more. The event will serve as a platform for industry leaders to showcase advancements that are set to influence the future of additive manufacturing.

Conclusion

The year 2025 is set to witness significant breakthroughs in 3D printing materials, including high-performance engineering plastics, composites, bio-based materials, high-temperature alloys, and conductive materials. These innovations will expand the capabilities of additive manufacturing, enabling applications across a broader range of industries. Engaging with events like TCT Asia 2025 will provide valuable insights into these advancements, offering a glimpse into the future of 3D printing technology.

References

[1] Ultracur3D RG 1100 B. Available at: https://www.raise3d.com/forward-am-ultracur3d-rg-1100-b (Accessed on: January 8, 2025)

[2] Ultracur3D RG 3280. Available at: https://www.raise3d.com/forward-am-ultracur3d-rg-3280 (Accessed on: January 8, 2025)

[3] High-Performance Carbon Fiber Reinforced PA6. Available at: https://www.farsoon-gl.com/news/farsoon-introduces-the-high-performance-carbon-fiber-reinforced-pa6-material-fs6130cf-f (Accessed on: January 8, 2025)

[4] Future Prospects of 3D Printing Materials. Available at: http://m.163.com/dy/article/JEK1KAG10532907I.html (Accessed on: January 8, 2025)

[5] Trends in Additive Manufacturing Materials. Available at: https://m.chinairn.com/news/20241218/165940856.shtml (Accessed on: January 8, 2025)

[6] Innovations in High-Temperature Alloys for Additive Manufacturing. Available at: http://m.163.com/dy/article/J60EAGTV051186GP.html (Accessed on: January 8, 2025)