In the pursuit of a greener and more sustainable world, individuals and businesses are reevaluating their everyday practices, including how they print documents and images. As the global push for sustainability intensifies, companies like G&G have taken their environmental responsibility and offered eco-friendly printing solutions.

The Rebirth of Cartridges

Did you know millions of cartridges are discarded and end up in landfills each year? However, G&G takes these cartridges on a journey of renewal. The company has taken a circular approach, where empty ink cartridges are given a new lease on life through the remanufacturing process. This process begins with a robust empties collection program. The company receives over 750,000 cartridges from collection agencies worldwide each month. These cartridges are then carefully inspected and sorted, skillfully disassembled, thoroughly cleaned and replaced with new components. This ensures that the cartridges are restored to their original functionality, guaranteeing optimum performance. By recycling cartridges, G&G significantly reduces the demand for new materials, reducing the environmental burden associated with cartridge production.

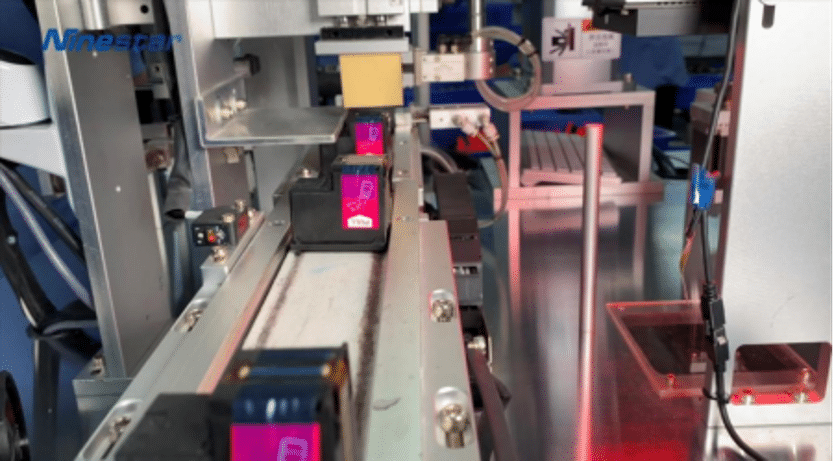

Efficient Remanufacturing Process

To boost efficiency and reduce waste, G&G has employed an automated production line. This innovative approach increases efficiency by an impressive 20% while saving up to 65% of the water that would have been consumed by traditional methods. This substantial reduction in water usage reflects G&G’s commitment to green initiatives, making their remanufacturing process even more eco-friendly.

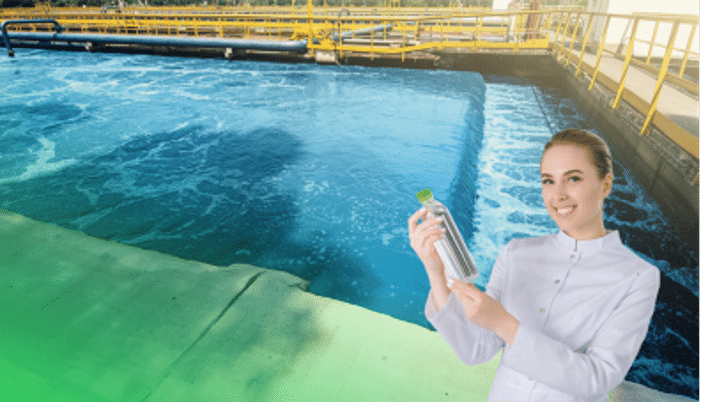

Water Treatment

One of the primary challenges faced by ink cartridge remanufacturers is water pollution resulting from cleaning used cartridges. Unfortunately, many companies neglect proper water treatment, which tarnishes the image of their remanufactured products as being environmentally friendly.

However, G&G‘s dedication to producing high-quality remanufactured cartridges does not come at the expense of the environment. By investing about 8 million RMB in their sewage treatment station, covering an area of 1500 square meters, G&G has demonstrated their commitment to sustainable practices. The sewage treatment station processes 800 cubic meters of sewage daily, partly from residual ink captured during the cleaning of used original cartridges for remanufacturing. By ensuring responsible wastewater treatment, G&G significantly reduces its environmental impact and sets a good example for others to follow.

G&G’s remanufactured ink cartridges are much more than just ink containers; they are symbolic of a green revolution in the printing industry. The company has taken their environmental responsibility and created a sustainable solution that reduces water and electronic waste, conserves resources, and minimizes carbon emissions. Your choice of G&G’s product not only contributes to waste reduction but also supports a more sustainable printing industry.