In modern hotel projects, fixed and loose furniture (FF&E) are not only core elements of interior decoration but also critical factors in enhancing the functionality and comfort of spaces. Ensuring that these pieces meet design requirements while offering optimal quality and performance within the budget is crucial to the success of the project. To achieve this, the early involvement of furniture manufacturers in the design development phase (ECI) and the implementation of Value Engineering (VE) processes are of utmost importance.

The ECI and VE processes help design teams control costs from the outset, optimize designs, and improve overall project economy and operability. This article will explore the role of furniture manufacturers in the design development process, specifically in implementing ECI and VE processes for fixed and loose furniture, along with the benefits these processes bring.

2. Overview of ECI (Early Contractor Involvement)

ECI (Early Contractor Involvement) refers to the early participation of furniture manufacturers in the design phase, typically starting from the preliminary design stage. During this phase, the furniture manufacturer collaborates closely with the design team, owners, architects, and other parties to provide professional advice and feedback. The primary goal of ECI is to avoid unreasonable designs or cost overruns by providing technical support, craft recommendations, and cost estimates early in the design process.

ECI Implementation Steps

Initial Design Communication

In the early stages of a project, furniture manufacturers and the design team engage in detailed communication to share project goals, design concepts, space layouts, and other key information. This ensures the manufacturer can propose suitable furniture solutions. At this point, the manufacturer may also offer expert opinions to ensure the design is feasible.

. Needs Analysis

Based on the overall hotel design, furniture manufacturers begin to plan fixed and loose furniture with respect to functionality, size, style, and other requirements. They provide feedback on the technical and craftsmanship requirements, such as the specific furniture needed for the lobby, restaurant, or guest rooms.

. Material and Craft Recommendations

During the ECI process, manufacturers may also suggest materials and craftsmanship to the design team. They help choose appropriate materials (e.g., eco-friendly boards, solid wood, metal fittings) and propose the best production methods to ensure the durability and quality of the furniture, based on the hotel’s specific needs.

. Environmental Considerations

For hotels located in coastal or other humid environments, furniture manufacturers consider the corrosion resistance of materials. For example, in coastal locations where salty air accelerates metal corrosion, manufacturers may recommend 304 stainless steel, which has strong corrosion resistance, ensuring the longevity of the furniture.

Benefits of ECI

ECI enables furniture manufacturers to better understand the project’s overall requirements early on, avoiding unnecessary design changes or revisions. By closely collaborating with the design team, potential technical challenges and cost issues can be identified early, ensuring seamless integration between design and production. Additionally, ECI helps maintain the project schedule, saving both time and costs.

4. Key Role of Furniture Manufacturers in the Design Development Process

Throughout the design development process, furniture manufacturers play a crucial role. They ensure that the design seamlessly aligns with production capabilities, especially during the early stages of ECI. By providing technical support, material recommendations, and manufacturing expertise, they assist the design team in creating feasible furniture solutions that meet the hotel’s needs.

Moreover, through the VE process, manufacturers ensure that the design can be executed without technical or production restrictions, thereby increasing production efficiency and reducing modification risks. By optimizing costs while maintaining high-quality production, they ensure that the final furniture delivered aligns with both the design vision and the budget.

5. Case Study

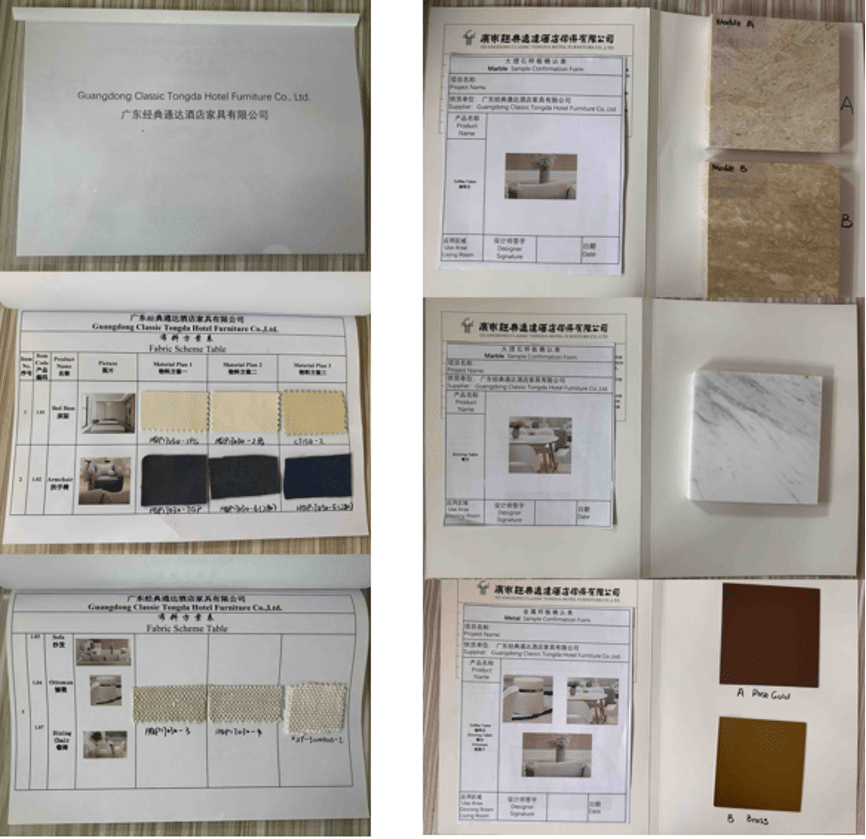

Classic Tongda Hotel Furniture, one of the best FF&E manufacturers in the world, plays an indispensable role in the design development process, particularly through the implementation of ECI and VE processes for fixed and loose furniture. These processes offer significant cost savings and design optimization. By participating early in the design phase, manufacturers provide valuable technical support and manufacturing advice.

For example, in a recent project for a 5-star hotel located near the sea, Classic Tongda Hotel Furniture’s expertise proved invaluable. Given the coastal location, where sea winds could accelerate corrosion, Classic Tongda recommended using 304 stainless steel for the metal parts of the furniture. This material is more durable than standard metals, offering better resistance to corrosion caused by the salty air, thus ensuring long-term durability and functionality. This proactive advice not only helped in maintaining the quality of the furniture but also optimized the project’s cost-effectiveness.

The VE process further optimized resources without sacrificing quality, enhancing the overall value of the hotel project. By integrating these processes, Classic Tongda contributed to a project that was both economically efficient and of exceptional quality.

6. Conclusion and Future Outlook

Hotel Furniture manufacturers play an indispensable role in the design development process, particularly through the implementation of ECI and VE processes for fixed and loose furniture. These processes offer significant cost savings and design optimization. By participating early in the design phase, manufacturers provide valuable technical support and manufacturing advice, ensuring feasibility and cost-effectiveness. The VE process helps optimize resources without sacrificing quality, improving the overall value of the hotel project.

Looking ahead, as smart technologies and eco-friendly materials continue to evolve, the role of furniture manufacturers will become increasingly vital. Leveraging advanced technologies, manufacturers will be able to provide more accurate cost estimates and optimized design solutions, bringing further innovation and value to hotel projects. For hotel furniture manufacturers, staying at the forefront of these trends will be essential to their success in an ever-evolving market.

By incorporating hotel furniture manufacturers as a key part of the design and development process, projects can achieve a perfect balance between cost, functionality, and design excellence.