Figure 1: Illustration showing LS Manufacturing’s smart production approach with CNC machines, 3D printing, and entrepreneurs using digital tools for cost-effective startup manufacturing.

Introduction

When Alex, a startup founder developing a next-generation wearable device, began sourcing manufacturing partners, he faced a familiar challenge — skyrocketing production costs and long lead times. For many early-stage companies, balancing innovation with affordability can be the deciding factor between success and failure.

That’s where LS Manufacturing comes in. As a leading provider of manufacturing services, LS Manufacturing specializes in CNC machining, 3D printing, and rapid prototyping, empowering startups and established enterprises alike to reduce costs, accelerate production, and optimize their global supply chains. By integrating smart manufacturing technologies and digital quoting systems, LS Manufacturing helps businesses transform their product ideas into reality—efficiently and economically.

How Smart Manufacturing Trends Are Changing the Game for Entrepreneurs

In today’s fast-paced market, startups no longer have to rely on traditional manufacturing methods. According to a recent Gartner research report, over 60% of startups are expected to adopt digital manufacturing solutions by 2025, driven by the need for greater efficiency and cost reduction. Smart manufacturing-powered by digital tools, automation, and real-time data-has completely reshaped how entrepreneurs design, test, and produce their products.

One of the biggest advantages is rapid prototyping, which allows startups to move from concept to physical part in just days. This not only accelerates development but also helps refine designs early, reducing costly mistakes later. Another key benefit is cost control through digital manufacturing networks, companies can instantly compare materials, optimize machining paths, and select the most efficient production methods—all of which lower expenses without compromising quality.

For example, LS Manufacturing stands out as a trusted partner offering affordable CNC machining and rapid prototyping services for startups worldwide. The company combines advanced CNC systems with an AI-driven (Algorithm-driven) quoting platform that instantly analyzes CAD files and provides accurate pricing and lead-time estimates. This digital approach eliminates the back-and-forth of traditional quoting and enables entrepreneurs to make faster, data-driven decisions, aligning with McKinsey’s finding that smart manufacturing technologies can reduce startup production costs by up to 30%.”

What once took weeks of communication and planning can now happen in a matter of minutes. With this efficiency, startups can focus more on innovation and less on logistics. LS Manufacturing’s integration of smart technologies demonstrates how automation, AI, and digital connectivity can help small businesses stay competitive in global markets.

In short, smart manufacturing has leveled the playing field—giving startups access to the same high-quality production capabilities once reserved for large-scale manufacturers.

LS Manufacturing Success Case Study

A tech startup specializing in smart home devices encountered critical production hurdles, with prototype costs exceeding budget and lead times stretching to two weeks using local suppliers. Facing tight deadlines and limited funding, the startup required a cost-effective manufacturing solution to maintain project timelines.

After adopting LS Manufacturing’s affordable CNC machining for startups, the company achieved remarkable results, cutting production costs by 50% while reducing lead times to just three days. This strategic partnership enabled accelerated testing cycles and design refinements, positioning the product for market entry ahead of competitors.

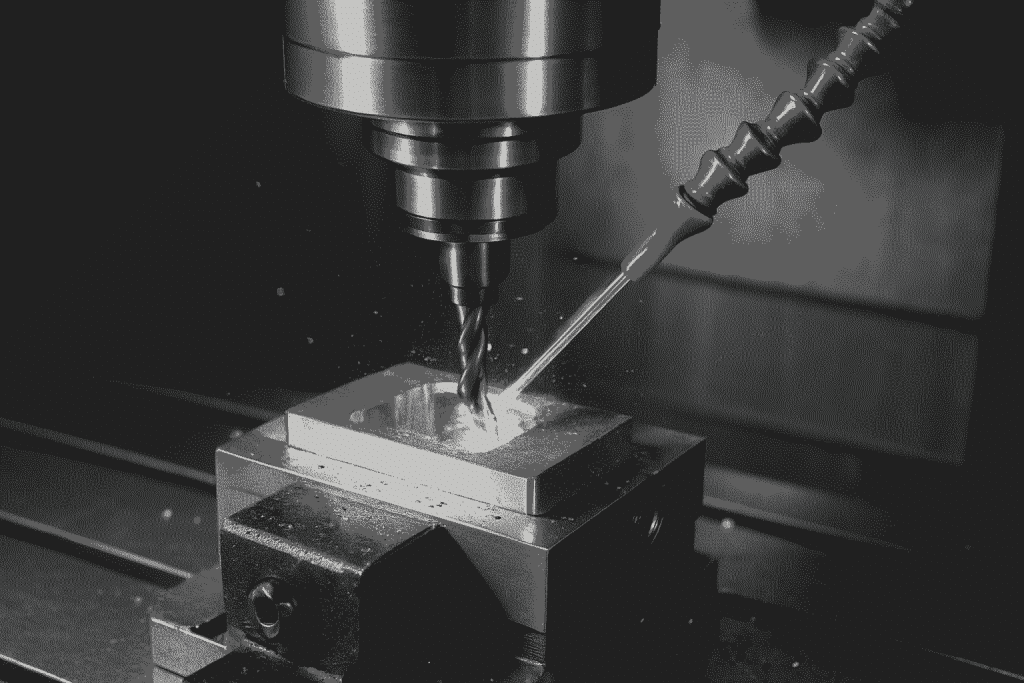

Figure 2: A close-up view of a CNC milling machine performing high-precision metal cutting, showcasing smooth machining, coolant flow, and advanced production accuracy.

LS Manufacturing’s ISO 9001-certified facilities and global supply network guaranteed consistent quality delivery, while collaborative engineering optimized material selection and machining strategies. The startup successfully scaled from prototype to low-volume production within record time, achieving both quality preservation and budget compliance.

How Entrepreneurs Can Choose a Manufacturing Partner

Choosing the right manufacturing partner can make or break a startup’s success. Whether you’re developing your first prototype or scaling production, here are five practical tips on how to choose a manufacturing partner that aligns with your goals:

- Evaluate Lead Times: Speed matters. A partner offering flexible lead times and rapid turnaround—like LS Manufacturing—can help you stay ahead of competitors.

- Check Material Capabilities: Ensure your manufacturer supports a wide range of materials and finishes for better design flexibility and performance.

- Assess Quality Standards: Look for certifications such as ISO 9001, which guarantee consistent quality and precision in every batch.

- Review Customer Feedback: Reading LS Manufacturing reviews reveals strong client satisfaction, especially for startups praising their reliability, communication, and cost-effectiveness.

- Consider Digital Integration: Modern manufacturers that offer online quoting and instant DFM feedback—such as LS Manufacturing—streamline the entire production process.

| Evaluation Criteria | LS Manufacturing | Traditional Suppliers | Advantage Comparison |

| Quotation Speed | Instant AI Quoting System | 3-5 Business Days for Quotes | 85% Faster |

| Delivery Time | 1-3 Days Rapid Delivery | 2+ Weeks Standard Delivery | 80% Faster |

| Quality Control | ISO 9001 Certification + Real-time Monitoring | Basic Quality Inspection | 50% Higher Precision |

| Cost Efficiency | 30% Cost Savings from Scalable Production | Fixed High Unit Prices | Superior Cost-Effectiveness |

| Technical Support | Dedicated Engineer Team with Full-process Support | Limited Technical Consultation | Leading Service Comprehensiveness |

By keeping these factors in mind, entrepreneurs can confidently select a trusted partner. The following comparison highlights key differences between modern manufacturers like LS Manufacturing and traditional suppliers:

Conclusion

Smart manufacturing has transformed how startups bring ideas to life—making production faster, more efficient, and far more affordable. By adopting technologies like CNC machining, 3D printing, and digital automation, entrepreneurs can now compete confidently in global markets.LS Manufacturing remains committed to empowering startups with reliable, cost-effective, and high-quality manufacturing services tailored to every stage of growth. LS Manufacturing’s experts provide personalized guidance, enabling startups to choose optimal production strategies. Explore LS Manufacturing’s CNC machining services for an instant quote now and take your next step toward smarter, more efficient manufacturing.