A professional report showcases that the global flooring market will hit a booming spike of over $517.74 billion by the end of 2028. The astounding figure reveals that the flooring market is certainly on the rise. And that’s why the different construction and flooring business leaders are taking a fancy to the industry’s reputable and trustworthy plastic extrusion machine manufacturers.

Not only that, but their keen interest in the matter has taken them to the point where they ask questions like, “how to distinguish between the LVT and PVC flooring production lines?” Therefore, this article will take you through all these curiosities, and by the end, you will be racking it in with a solution that is bound to lead to immense gains and profits. So let’s figure out everything straight into the discussion.

What Is an LVT and PVC Flooring Production Line?

1. LVT Flooring Production Line

LVT is the abbreviated form of Luxury Vinyl Tiles. To flawlessly create these flooring tiles or planks to improve the realistic features of traditional vinyl sheets, a distinct set of plastic extrusion machines is employed, typically known as the LVT flooring production line.

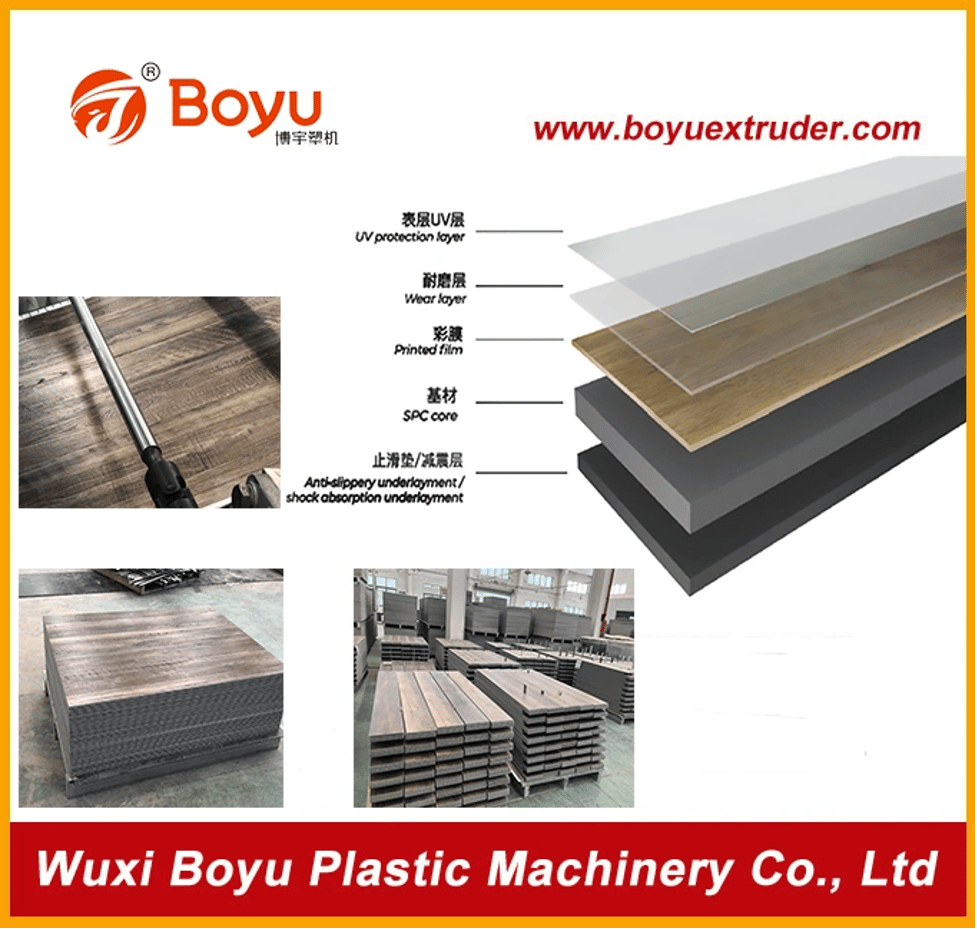

Similar to the PVC production line process, where a different group of plastic extrusion equipment is deployed, LVT flooring machines manufacture multi-layered plastic extrusion solutions.

2. PVC Flooring Production Line

PVC is an abbreviation widely used to define Poly Vinyl Chloride products, with which the most acknowledged product is PVC flooring. Such a particular PVC flooring is carried out through the various features of impeccably capable PVC flooring production line tools and operational techniques. Out in the commercial world, the most extraordinary flooring and roofing models and some other substantial building materials are all made from the processing of plastic extrusion equipment.

What Are the Benefits of an LVT Flooring Production Line?

1. Durability:

On the one hand,LVT production lines are capable of providing hard-wearing with durable LVT flooring designs that are in high demand in the global domestic construction market. On the other hand, LVT production lines are durable enough to operate in various environments.

2. Highly Accurate Functions:

With LVT flooring production machines, a unique finished product can be cut accurately into preferred shapes and sizes with complete automation.

3. Exquisite Choice for Commercial Production:

Like a PVC flooring production line, LVT flooring equipment can be used for high-volume manufacturing of commercial items.

4. Versatile Machinery Features:

The latest models of LVT flooring lines feature versatile functions, including waterproof, automatic, high output designs, etc.

What Are the Benefits of a PVC Flooring Production Line?

1. Easy to Operate:

Having a simplified control system, the PVC flooring production line follows an efficient and easy-to-operate construction process that delivers products with downright precision of variable contour options.

2. Immune to Environmental Chemicals:

Performing in different chemical industrial areas, PVC flooring production lines have strong resistance properties to withstand corrosion, acidic, alkaline, and other small fluid-containing surroundings.

3. Quick and Efficient Production:

The efficient mechanical structure of the PVC flooring production line offers a rapid manufacturing process with a premium quality output for high-volume construction projects. This is advantageous for both the manufacturer and the customer.

4. Material Optimization Flexibility:

The automated material processing from the outset of the manufacturing gives the PVC flooring production line an edge of great and unbeatable final product confirmation. The computer-operated features of this plastic extrusion equipment open creative doors to diverse and incredibly profitable outcomes for business people.

Boyu: A Reliable Flooring Production Line Manufacturer

After going through the benefits of the LVT and PVC flooring production lines, you would probably understand that these production lines can significantly help various commercial manufacturing businesses to create a strong foothold in the industry and expand their line of work to a global scale in a short matter of time.

But they need to partner with reliable plastic extrusion machine manufacturers that can provide them with the exact kind of plastic extrusion equipment they need to execute their production operations accordingly. Knowing that different manufacturing companies have different flooring lines’ needs, it is wise to go for a plastic extrusion equipment manufacturer who confirms to have a wide variety of flooring production lines at reasonable prices.

Boyu follows the market’s demand, which makes it a profitable and worthwhile investment for any business that aims for a commercially successful future. With over two decades of extrusion experience, Boyu provides top-of-the-line quality LVT and PVC flooring production line equipment that can simultaneously cater to a broad spectrum and requirements of businesses. In addition, Boyu is the perfect manufacturer that sets long-term collaboration as the core prerequisite. Therefore, for any questions about extrusion machines, feel free to contact them.