Figure 1: A close-up of precision CNC machining, showing a milling tool shaping a metal component. The image highlights high accuracy, smooth surface finishes, and advanced rapid prototyping technology used by JS Precision.

Introduction

In the race to bring products to market, speed from concept to physical part is often the difference between success and failure. Modern industries—from aerospace and automotive to medical and consumer electronics—demand not only faster development cycles but also unmatched precision in every prototype and component. This growing pressure has placed CNC machining and rapid prototyping at the heart of innovation.

These two technologies work hand in hand: rapid prototyping accelerates design validation, while precision CNC machining ensures tight tolerances and production-level quality. Together, they bridge the gap between creative ideas and tangible results, empowering engineers and product designers to iterate, test, and launch with confidence.

This guide delves into how precision CNC machining synergizes with rapid prototyping, revealing how industry leaders like JS Precision leverage these advanced manufacturing technologies to help clients accelerate innovation, reduce time-to-market, and gain a lasting competitive edge in today’s fast-moving industrial landscape.

Demystifying CNC Machining: Beyond the Basics

CNC machining is more than just an automated cutting process—it’s the foundation of modern precision manufacturing. Unlike additive manufacturing (3D printing), which builds objects layer by layer, CNC machining is a subtractive process, removing material from a solid block (metal or plastic) to create parts with exceptional precision.

There are several types of CNC machines, including mills, lathes, routers, and multi-axis machining centers. Each type offers different capabilities, but all share one goal—achieving consistent accuracy and repeatability.

| Process | Accuracy | Material Range | Cost | Production Speed |

|---|---|---|---|---|

| CNC Machining | ±0.005 mm | Metals & Plastics | Moderate | Fast |

| 3D Printing | ±0.1 mm | Polymers & Metals | Low | Very Fast |

| Injection Molding | ±0.02 mm | Plastics | High (tooling) | Very Fast (mass) |

When it comes to complex geometries, multi-axis machining shines. While 3-axis machines handle simpler cuts, 5-axis CNC machining allows simultaneous movement across multiple directions. For instance, manufacturers equipped with advanced 5-axis CNC technology, like JS Precision, can machine intricate parts in a single setup—drastically reducing lead time and improving accuracy for even the most demanding projects.

The Strategic Edge of CNC Machining: Five Advantages That Redefine Manufacturing

CNC machining stands apart as a cornerstone of modern manufacturing—not just for its precision, but for the strategic advantages it delivers across industries. From medical devices to aerospace components, its capabilities empower engineers to achieve performance, reliability, and scalability at every stage.

CNC machining offers five core strategic advantages that redefine modern manufacturing:

1. Unmatched Precision & Repeatability

CNC machining achieves tolerances as tight as ±0.005 mm (aligning with international standards such as ISO 2768), ensuring every part meets critical standards. This level of precision is essential in fields like aerospace and medical technology, where even the smallest deviation can compromise performance or safety.

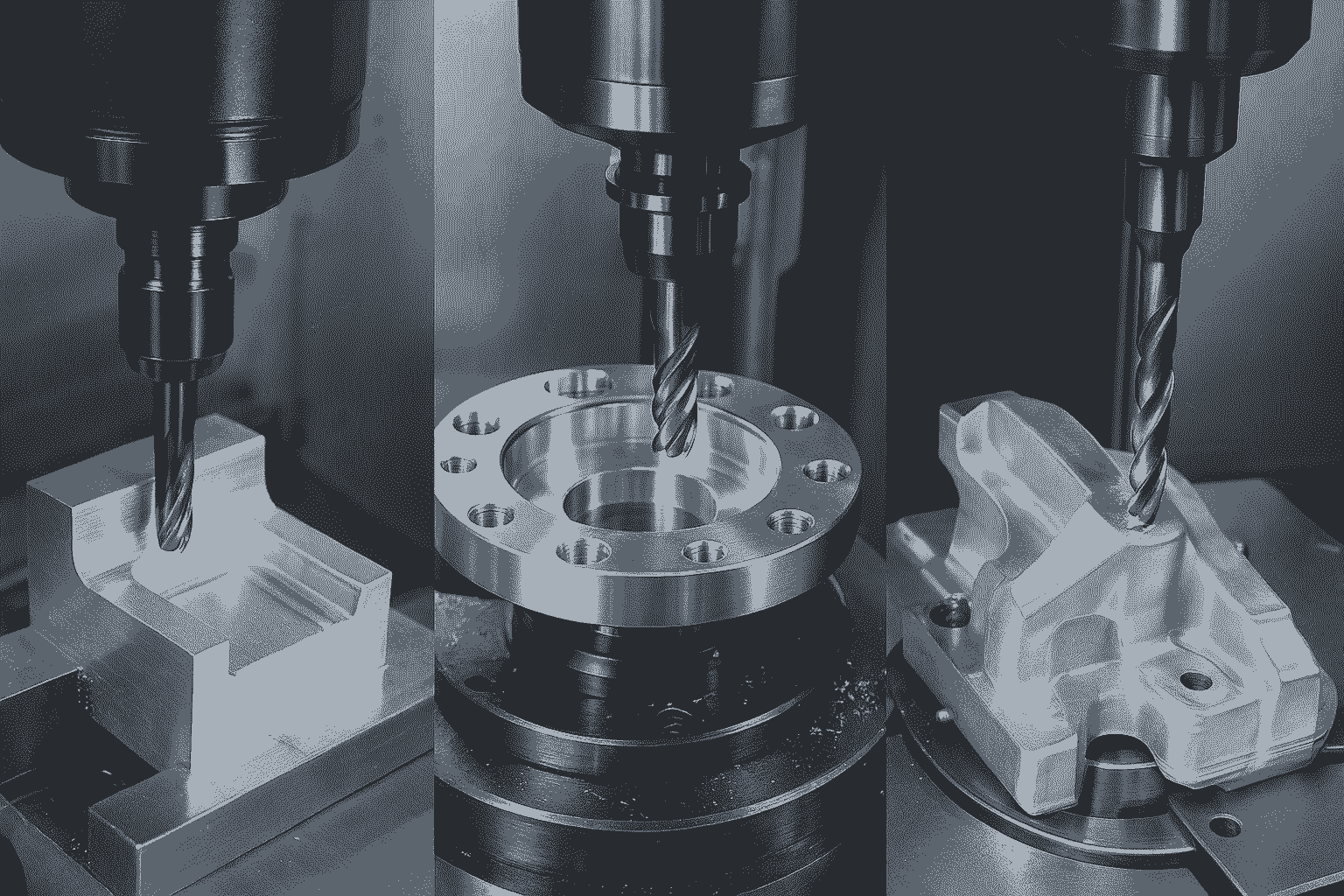

Figure 2. The image showcases a CNC machine in action across three sections, illustrating precision cutting, drilling, and finishing operations on diverse metal components in a streamlined, high-tech manufacturing environment.

2. Vast Material Compatibility

CNC machining supports an extensive range of materials, from aluminum, stainless steel, and titanium to engineering plastics like PEEK and ABS. This flexibility enables seamless development across the full product lifecycle—from concept to end-use parts.

3. Superior Part Strength & Durability

Unlike 3D printing’s layered structures, CNC parts are carved from solid billets, resulting in isotropic strength and greater durability—ideal for load-bearing or high-stress applications.

4. Seamless Transition from Prototype to Production

CNC machining offers cost-effective scalability, allowing teams to shift smoothly from rapid prototyping to low-volume production without retooling or sacrificing accuracy.

5. Excellent Surface Finish Quality

With diverse finishing options—anodizing, plating, bead blasting, and polishing—CNC machining ensures both functionality and visual appeal. These five advantages make CNC machining a strategic choice. To fully leverage them, partnering with an expert in high-precision CNC machining services is key. Companies like JS Precision provide not only the technological capability but also the material and finishing expertise to ensure your project’s success from prototype to production.

In Practice: How CNC & Rapid Prototyping Are Revolutionizing Key Industries

The impact of CNC machining and rapid prototyping extends far beyond manufacturing floors—it’s transforming how entire industries innovate, test, and bring products to life. From aerospace engineering to everyday electronics, these technologies empower designers to turn bold ideas into tangible, high-performance realities.

Aerospace Industry – Lightweight Precision for Flight

In aerospace, every gram counts. Engineers rely on lightweight metal machining to produce intricate brackets, housings, and structural fixtures that comply with SAE International’s aerospace material specifications (AMS standards) for optimal strength-to-weight ratios.

Medical Industry: Safe, Functional, and Fast

In the medical field, medical-grade CNC machining is critical. It enables the production of surgical guides, implant prototypes, and custom tools with micron-level accuracy, ensuring patient safety and compliance. For instance, JS Precision recently assisted a med-tech startup by delivering a functional prototype for a new surgical tool within just 5 days. This accelerated timeline enabled rapid clinical testing and paved the way for faster regulatory approval (as outlined in FDA guidelines for medical device prototyping), showcasing the power of rapid prototyping in bringing life-saving devices to market quicker.

Automotive Industry – Driving Innovation with Speed

Automakers leverage automotive rapid prototyping to create and refine engine parts, transmission components, and aerodynamic prototypes before full-scale production. CNC machining’s consistency ensures performance validation without costly delays.

Consumer Electronics – Aesthetics Meet Precision

For consumer tech brands, high-finish CNC machining allows the creation of sleek device housings, heat sinks, and precision connectors. The combination of tight tolerances and premium surface finishes helps products look stunning and perform flawlessly—proving that precision engineering powers both form and function in the modern marketplace.

Choosing Excellence: How JS Precision Transforms Ideas into Market-Ready Reality

When precision, speed, and reliability define success, JS Precision stands as a true manufacturing partner—bridging the gap between design and production with technology-driven expertise. The company’s value lies not only in its machinery but in its commitment to delivering smarter, faster, and more dependable solutions.

Advanced Equipment Fleet

JS Precision operates an industry-leading lineup of machines, including DMG MORI 5-axis CNC systems, capable of producing intricate geometries in a single setup. This advanced equipment ensures superior accuracy, efficiency, and reduced lead time for every project.

Expert Engineering Team

Every project begins with an intelligent design review. JS Precision’s engineers provide Design for Manufacturability (DFM) feedback to help clients refine their designs, minimize costs, and enhance part performance before machining even begins.

Rigorous Quality Control

Precision is verified, not assumed. The company employs CMM inspection systems, optical scanners, and in-process measurement tools to guarantee every part meets exact specifications.

Rapid-Response Quoting & Project Management

With 24-hour quotes and fast turnaround times, JS Precision ensures your prototypes and production parts are delivered on schedule without compromising quality.

At JS Precision, we are more than just a machine shop—we are your innovation partner. Our team helps transform your designs into high-performance parts with confidence and speed. Get an instant quote today on www.cncprotolabs.com.

The Future Frontier: Where Intelligence Meets Precision in CNC Manufacturing

The future of CNC machining is not just about cutting metal—it’s about integrating intelligence, automation, and connectivity into every stage of production. As industries evolve toward smart manufacturing, the next wave of innovation is reshaping how precision parts are designed, programmed, and produced.

Automation is taking center stage through robotic loading and unattended machining, enabling 24/7 production while reducing human error and downtime. Robots now seamlessly handle part exchanges, ensuring efficiency even in high-mix, low-volume manufacturing environments.

Meanwhile, artificial intelligence (AI) is revolutionizing toolpath optimization, aligning with MaKinsey’s findings on advanced robotics and process innovations that are reshaping modern manufacturing, automatically selecting ideal cutting strategies to extend tool life, reduce waste, and improve consistency. AI-driven machining also learns from past operations, continually enhancing performance with each cycle.

Another groundbreaking shift comes from digital twin technology—virtual replicas of machines and processes that allow engineers to simulate, predict, and perfect manufacturing before a single cut is made.

JS Precision is actively investing in these smart manufacturing technologies to ensure clients stay ahead of the curve—combining precision craftsmanship with intelligent automation to deliver faster, smarter, and more reliable solutions for the industries of tomorrow.

Conclusion

From concept to creation, CNC machining and rapid prototyping have become the driving force behind modern innovation—turning bold ideas into functional, high-performance products faster than ever before. Their ability to deliver precision, flexibility, and scalability empowers engineers to push boundaries across industries like aerospace, medical, and automotive.

In today’s competitive landscape, leveraging high-precision CNC machining services and low-volume rapid prototyping solutions is no longer an option, but a necessity for innovation. As we’ve explored, these technologies are pivotal across aerospace, medical, automotive, and consumer electronics industries.

JS Precision stands ready as your partner in this journey. We combine state-of-the-art technology, rigorous quality control, and expert engineering support to transform your concepts into market-ready realities—fast.

Ready to accelerate your next project?

Limited-time offer: Contact JS Precision today to claim your free DFM analysis and instant quote, and accelerate your project within 24 hours. Experience the difference where unparalleled speed meets uncompromising precision.