Automatic gates in San Jose, CA empower homeowners with enhanced security and seamless access, yet they often encounter persistent repair issues that interrupt daily routines. Understanding what are the most common gate repair issues in San Jose homes helps you address mechanical wear, electrical faults, structural damage, access control glitches, and climate-driven deterioration before small problems become costly replacements. This comprehensive guide previews five key problem areas—mechanical failures, electrical malfunctions, structural damage, access control system problems, and San Jose’s unique environmental impacts—and explains practical fixes. Along the way, you’ll learn how Automatic Gate Masters’ expert technicians apply precise diagnostics, OEM parts, and 24/7 emergency response, ensuring you can request a free estimate or schedule service with confidence.

What Are the Most Common Mechanical Failures in San Jose Automatic Gates?

Mechanical failures occur when moving parts wear out or lose alignment, causing gates to sag, stick, or grind. These issues undermine gate operation and safety, yet many homeowners overlook early symptoms. Recognizing worn hinges, faulty rollers, and misaligned tracks—and knowing when to lubricate them—prevents extensive repairs and restores smooth functionality.

How Do Worn Hinges Cause Gate Sagging and How Can You Fix Them?

Worn hinges lead to gate sagging by allowing the leaf to drop under its own weight, which increases strain on the motor and hardware. You can correct sagging hinges by:

- Replacing pin-and-bushing hinge sets with OEM-certified hardware.

- Adjusting hinge mounting plates to restore level alignment.

- Reinforcing hinge bolt holes with metal backing plates for lasting support.

Addressing hinge wear promptly supports proper gate alignment and prevents motor overload that often follows untreated sagging.

What Are the Signs of Faulty Rollers and Track Misalignment?

Faulty rollers and misaligned tracks disrupt the smooth travel of sliding gates by producing grinding noises and uneven movement. Common indicators include:

- Grinding or scraping sounds when the gate moves.

- Visible debris buildup or bent track sections.

- Excessive play between roller wheels and track surfaces.

Detecting roller wear early enables targeted roller replacement or track realignment, which restores consistent motion and reduces motor stress.

How Does Gate Misalignment Affect Operation and What Are the Solutions?

Gate misalignment prevents sensors from detecting the gate position correctly, causing jerky starts or failure to open fully. Misalignment arises from ground settling, improper hinge adjustments, or bent frame sections.

| Component | Fault Indicator | Corrective Action |

| Sliding Gate | Side-to-side drift | Shim track base and realign with laser level |

| Swing Gate | Uneven leaf closing | Adjust hinge plates and re-bolt mounting |

| Gate Leaf Frame | Twisted or bowed section | Straighten frame; weld reinforcement plates |

Realignment restores sensor accuracy, reduces wear on rollers and hinges, and ensures reliable automated cycles.

When Should You Lubricate Hinges and Rollers to Prevent Mechanical Failures?

Regular lubrication prevents metal-on-metal friction that accelerates wear. San Jose homeowners should:

- Lubricate hinges, rollers, and track guides every three months.

- Use a silicone-based lubricant to resist dust accumulation.

- Wipe away debris before applying lubricant to ensure even coverage.

Consistent lubrication enhances component lifespan and sustains smooth gate movement, reducing the frequency of mechanical repairs.

How Can Electrical Malfunctions Disrupt Your Automatic Gate in San Jose?

Electrical malfunctions interrupt power flow or sensor communication, leading to complete gate stoppage or unsafe operation. Whether it’s a gate opener failure, faulty sensor, wiring issue, or remote control glitch, understanding each cause and repair approach restores secure access and dependable performance.

What Causes Gate Opener Failures and How Are They Repaired?

Gate opener failures often stem from motor overload, worn brushes, or heat-damaged circuit boards. Repair steps include:

- Inspecting amperage draw to identify motor strain.

- Replacing worn carbon brushes and testing the motor windings.

- Swapping out the control board with a factory-approved replacement.

Restoring opener health promotes consistent automation and prevents sudden shutdowns that trap vehicles or compromise security.

How Do Faulty Gate Sensors Affect Gate Safety and Function?

Gate sensors (photo-eyes) stop gate movement when the beam is interrupted; misaligned or dirty sensors can falsely signal obstructions, causing the gate to reverse or refuse to close. Troubleshooting steps:

- Clean sensor lenses with a microfiber cloth and isopropyl alcohol.

- Realign housings using a straightedge to ensure beam continuity.

- Test sensor circuitry for voltage consistency and replace damaged units.

Proper sensor operation safeguards people and vehicles by ensuring the gate only moves when the pathway is clear.

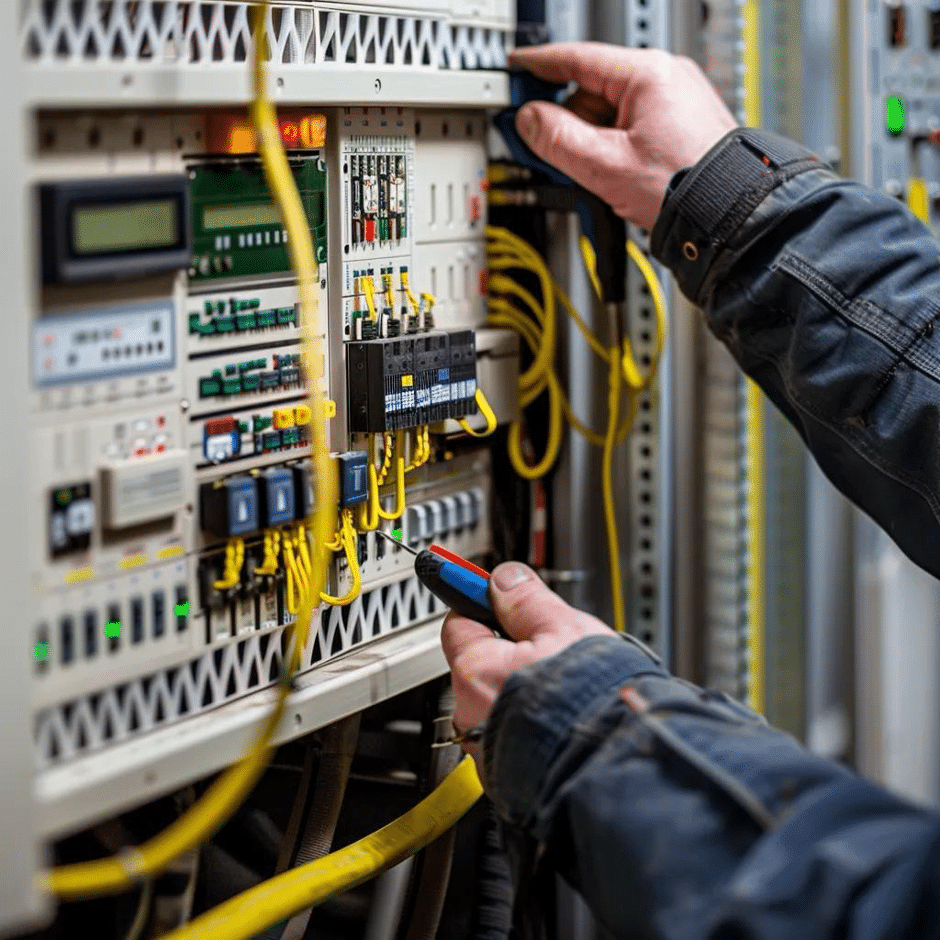

What Are Common Wiring and Control Panel Issues in Automatic Gates?

Wiring faults and control panel failures often result from rodent damage, moisture ingress, or loose terminal connections. Key repair actions:

- Inspecting wiring harnesses for chewing or cracking; replace afflicted sections with UV-resistant cable.

- Tightening control panel terminals and applying dielectric grease to prevent corrosion.

- Resetting or reprogramming control panel parameters after component replacement.

Robust wiring and a secure control panel casing boost overall system reliability and minimize intermittent failures.

How Does Remote Control Malfunction Impact Gate Access and How to Troubleshoot?

Remote controls that lose programming or exhibit range issues hinder authorized entry. Troubleshooting involves:

- Verifying battery voltage and replacing cells if below manufacturer thresholds.

- Re-syncing remotes to the gate receiver following OEM-mandated pairing procedures.

- Scanning for radio interference sources and adjusting receiver frequency channels.

Resolving remote malfunctions ensures seamless gate activation and preserves property access for residents and guests.

What Structural Damages Are Common in San Jose Gates and How Can You Repair Them?

San Jose’s sun, occasional rain, and seismic shifts contribute to structural damage—rust, bent panels, and compromised posts undermine gate integrity. Spotting these issues early and applying corrosion control or reinforcement prevents premature gate failure and extends service life.

How Does Rust and Corrosion Affect Gate Panels and Posts?

Rust corrodes metal thickness, weakening panels and posts until they buckle or fracture under load. Effective countermeasures include:

- Grinding away surface rust to reveal bare metal.

- Applying rust-inhibiting primer and high-build enamel paint.

- Installing sacrificial anodes on posts in high-humidity zones.

Treating corrosion promptly protects the gate’s structural integrity and preserves its aesthetic finish.

Corrosion and Environmental Impact

American Galvanizers Association, “Corrosion Protection” (2023)

What Are the Signs of Bent or Damaged Gate Panels?

Bent panels create gaps that allow misalignment and sensor misfires. Look for:

- Visible warping along panel edges.

- Uneven spacing between panel sections and posts.

- Panels rubbing against each other or the ground.

Panel straightening with hydraulic presses or localized welding reinforcement restores uniform movement and prevents binding.

How Can Weather and Environmental Factors Cause Structural Damage?

San Jose’s moderate rains followed by hot, dry summers accelerate thermal expansion and contraction, stressing welds and fasteners. Soil erosion from seasonal runoff can undermine post foundations and shift gate alignment. Utilizing weather-resistant hardware and installing concrete post footings counteracts these effects and maintains gate stability.

When Is Gate Post Repair or Reinforcement Necessary?

Gate post damage becomes critical when visible cracks or tilting exceed 2° from vertical. Repair options include:

- Slotting and sleeving new steel posts inside existing columns.

- Injecting high-strength grout into foundation voids.

- Welding reinforcement plates around the base to resist future shifts.

Timely post reinforcement prevents gate collapse and reduces risks of expensive full-post replacement.

What Access Control System Problems Do San Jose Homeowners Encounter?

Integrated access control systems—keypads, intercoms, card readers, biometric scanners—enhance security but introduce electronic vulnerabilities. Malfunctions in any component can lock out residents or compromise perimeter protection.

How Do Keypad and Card Reader Malfunctions Affect Gate Access?

Keypad issues range from worn-out buttons to corrupted firmware, while card readers may fail to read credentials due to antenna faults or weather damage. Repair steps:

- Replacing membrane keypads with weather-sealed models.

- Updating firmware via manufacturer tools and clearing memory dumps.

- Cleaning or replacing RFID antennas to restore read range.

Functional keypads and card readers maintain secure, frictionless access for authorized users.

What Are Typical Intercom System Troubleshooting Steps?

Intercom failures often involve poor audio quality or no call signal. Troubleshooting includes:

- Inspecting handset wiring for loose connectors and crimp integrity.

- Testing speaker and microphone elements with a multimeter.

- Upgrading to VoIP-compatible intercom modules for clearer transmission.

Reliable intercoms support visitor screening and emergency communication at the gate.

How Can Biometric Scanner Failures Be Diagnosed and Fixed?

Biometric scanners may misread fingerprints or facial patterns due to lens contamination or software drift. Corrective actions:

- Calibrating the scanner with manufacturer-provided test fingers.

- Cleaning optical surfaces with lens-grade solutions.

- Re-installing the biometric software package and restoring default settings.

Accurate biometric performance enhances access security and reduces false rejects.

Why Is Professional Access Control System Repair Important for Security?

Proper calibration, secure firmware updates, and encrypted data paths require specialized training and certified tools. Professional repair ensures your system adheres to UL 325 safety standards, maintains audit-grade logs, and integrates seamlessly with gate automation for uncompromised perimeter defense.

How Does San Jose’s Climate and Wear Affect Automatic Gate Longevity?

San Jose’s Mediterranean climate—mild, moisture-laden winters and hot, dry summers—accelerates wear on gate electronics and metal hardware. Understanding local weather impacts and combining regular maintenance with timely professional service extends gate lifespan and avoids unexpected failures.

What Weather Conditions in San Jose Cause Gate Wear and Tear?

Morning fog and dew introduce moisture that promotes corrosion in unprotected components, while midday heat cycles expand metal parts. Seasonal microtremors can loosen mountings. These factors collectively wear down hinges, rollers, and control panels, necessitating climate-adapted maintenance schedules and hardware selections.

How Can Regular Maintenance Extend Your Gate’s Lifespan?

Routine maintenance—monthly inspections, quarterly lubrication, and annual professional tune-ups—prevents minor issues from compounding. Scheduled checks of motor amperage, sensor alignment, and structural fasteners detect abnormal wear patterns. This proactive regimen supports reliable automation and reduces total cost of ownership.

Gate Maintenance and Longevity

National Association of Home Builders, “Home Maintenance Checklist” (2024)

What Are Simple DIY Maintenance Tips for San Jose Homeowners?

Homeowners can improve gate performance by:

- Wiping down sensor lenses with alcohol and lint-free cloths.

- Applying a silicone spray to hinges, rollers, and track guides.

- Tightening visible bolts on hinges and control boxes.

- Clearing debris and vegetation from the gate path.

These easy tasks promote smooth operation and deter costly repairs.

When Should You Schedule Professional Gate Maintenance Services?

Schedule a professional inspection when you notice irregular noises, slowing gate speed, or intermittent sensor errors. Annual preventive service by certified technicians includes in-depth diagnostics, system reprogramming, and component replacement using OEM parts, ensuring peak performance year-round.

How Does Automatic Gate Masters Fix These Common Gate Repair Issues in San Jose?

Automatic Gate Masters applies a systematic diagnostic process and proven repair protocols to resolve all five major issue categories. Our technicians combine deep local experience with certified training to deliver reliable solutions.

What Is the Diagnostic Process for Identifying Gate Problems?

Technicians begin with a comprehensive inspection that includes:

- Visual examination of mechanical components and structural alignment.

- Electrical testing of motor amperage, control board diagnostics, and sensor calibration.

- Access control audit evaluating keypad, intercom, and biometric device integrity.

This methodical approach isolates root causes and informs cost-effective repair strategies.

How Do Expert Technicians Use OEM Parts for Reliable Repairs?

We exclusively use OEM-approved hinges, rollers, motors, and control boards that match your gate’s specifications. OEM parts deliver precise tolerances and manufacturer-backed warranties, which enhance longevity and maintain original system performance.

What Emergency Repair Services Are Available for San Jose Homeowners?

Our 24/7 emergency dispatch ensures rapid response to gate failures that jeopardize security or trap vehicles. Emergency services include on-site diagnostics, temporary bypass solutions, and full-repair work using mobile service units stocked with common OEM parts.

How Can You Request a Free Estimate or Service Call?

To schedule a complimentary on-site estimate or emergency repair, call Automatic Gate Masters at (650) 560-4646 or complete the online service request form at our website. Our team will confirm your appointment and provide transparent pricing before any work begins.

What Preventative Maintenance Tips Help San Jose Homeowners Avoid Gate Repairs?

Proactive maintenance reduces repair frequency, extends gate lifespan, and safeguards your investment. Implementing a structured maintenance routine keeps all components functioning smoothly.

How Often Should You Inspect and Lubricate Your Automatic Gate?

Inspect visual alignment and fasteners monthly, and lubricate hinges, rollers, and track guides quarterly with a silicone-based spray. Consistent lubrication limits metal abrasion and preserves gate movement fluidity.

What Are the Key Steps in Cleaning Sensors and Electrical Components?

- Power down the gate system before servicing.

- Wipe sensor lenses and reflectors with isopropyl alcohol.

- Check wiring terminations for corrosion and apply dielectric grease.

- Verify control board LED indicators for error codes.

Clean and protected electronics sustain flawless automation and reduce false reversals.

How Can You Identify Early Signs of Mechanical or Structural Issues?

Watch for subtle cues such as new grinding noises, slight gate droop, or uneven movement patterns. Early detection through routine observation prevents small misalignments from evolving into major failures.

What Tools and Products Are Recommended for Gate Maintenance?

Keep on hand:

- Silicone lubricant spray for hinges and rollers

- Microfiber cloths and isopropyl alcohol for sensor cleaning

- Adjustable wrench set for fastener tightening

- Level and straightedge for realigning tracks and hinges

Using these tools ensures safe, effective DIY upkeep between professional visits.

Consistent preventative care and strategic professional support keep your automatic gate operating reliably in San Jose’s unique climate. By following these guidelines and entrusting repairs to trained experts, you can protect your property’s security and convenience for years to come.