In fields where precision is non-negotiable, the dynamometer force gauge is essential for accuracy and reliability. These devices, essential in measuring tensile and compressive forces, are pivotal for engineers, manufacturers, and researchers alike. Ensuring that force is applied safely and effectively is foundational in product testing, quality assurance, and various research and development initiatives. With technological advancements like the GD-200 3H, understanding how dynamometer force gauges operate has become increasingly important. Below, we delve into the functionalities of GD dynamometers, types, selection criteria, maintenance, and real-world applications in various industries.

Understanding Dynamometer Gauges and Their Role in Precision Measurement

Dynamometers, at their core, are designed to measure force exerted across a surface or through a component. The precision these instruments offer is unmatched, providing users with detailed insights into the amount of force being used or resistance being encountered. These are built to deliver accurate readings that are critical for ensuring product compliance with industry standards and safety regulations.

The role of force gauges extends beyond simple measurement; they provide data that can optimize processes, improve product design, and increase operational efficiency. By giving precise measurements, these tools help in identifying areas where materials can be conserved or where structural integrity can be enhanced. The data gathered is instrumental in advancing material science and engineering practices.

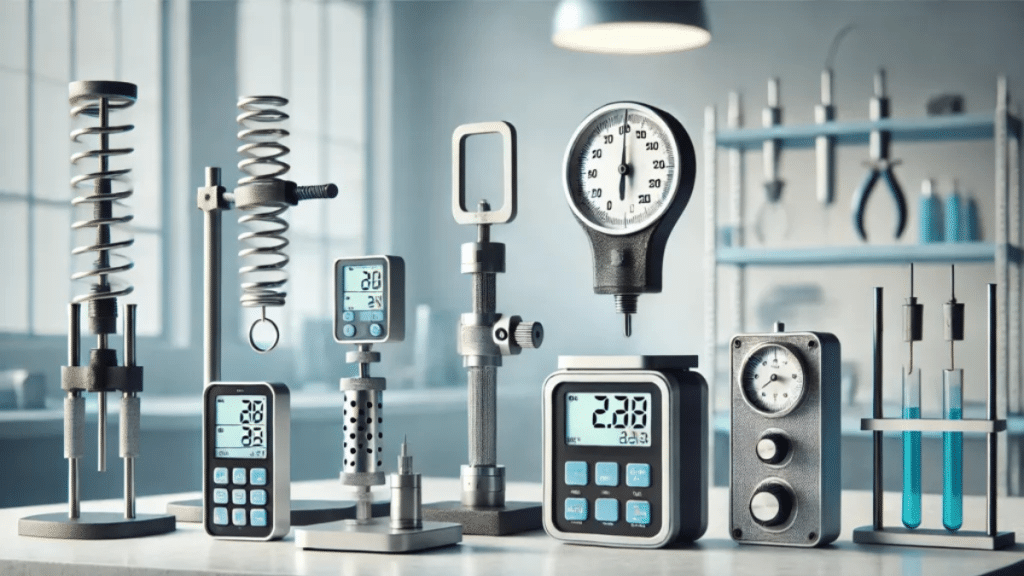

Exploring the Various Types of Dynamometers

Dynamometer force types come in several varieties, each tailored to specific measurement needs. Mechanical force types are time-tested tools that use a spring mechanism to measure force. They are simple to use, portable, and do not require a power source, providing quick readings in field conditions. However, they might not offer the precision that some modern applications require.

Digital force types represent the evolution of this technology, offering enhanced accuracy, easy-to-read electronic displays, and data logging capabilities. These features make them indispensable in situations where force measurements need to be recorded over time for analysis or where superior precision is necessary. Moreover, digital force types often have connectivity options for integration with computer systems for further analytical work.

Hydraulic force types use a fluid-filled chamber to measure force applied; the pressure within the chamber corresponds to the force exerted. These are often used in high-capacity scenarios like industrial equipment testing, where they are renowned for their durability and ability to handle extreme forces. However, their larger size and need for calibration with hydraulic fluid make them less convenient for smaller or more refined tasks.

Key Features To Look for When Selecting a Dynamometer

When selecting a dynamometer force gauge, it’s imperative to consider several key features that can affect performance and applicability. Accuracy is at the forefront, as a device that cannot provide precise readings is of little use in a professional setting. It’s also essential to assess the measurement range to ensure the device can handle the expected force spectrum for specific tasks.

Another important consideration is the ease of use and readability of the display. A dynamometer with a user-friendly interface and clear output is crucial for minimizing errors during testing. For those looking to incorporate data logging into their procedures, selecting a force gauge with built-in memory and connectivity options, such as USB or Bluetooth, is a smart choice.

Durability and build quality should also influence the selection process. The device should be robust enough to withstand the working environment, whether that’s in a clean lab or a rough industrial setting. Additionally, it’s important to choose a dynamometer that has been designed with ergonomics in mind, as this can significantly impact the efficiency and comfort of the user during prolonged use.

Altogether, dynamometer tension gauges are invaluable tools that serve a diversity of sectors with their ability to deliver precise and repeatable force measurements. Overall, understanding and utilizing these devices properly is a cornerstone of technological advancement and quality assurance across many fields.