As the world increasingly pivots towards sustainable energy solutions, platforms like RENEO 2024 stand at the forefront, offering a stage to showcase the latest breakthroughs in renewable energy and battery technology. This annual exhibition serves as a melting pot for innovators, researchers, and industry leaders to unveil cutting-edge advancements that have the potential to change how people harness and store energy. Against this backdrop of innovation and progress, SZJ Automation’s participation in RENEO 2024 holds particular significance. With a focus on battery manufacturing turnkey automation solutions, SZJ Automation is poised to demonstrate its commitment to driving efficiency and scalability in the renewable energy sector.

How Much Do You Know about RENEO 2024?

Nestled within the historic and vibrant city of Budapest, Hungary, the Budapest Fair Centre emerges as a beacon of innovation and progress in the realm of renewable energy and battery technology. From April 20th to April 24th, RENEO 2024, organized by Hungexpo, will transform this venue into a bustling hub of ideas, discussions, and groundbreaking demonstrations. Drawing participants from across the globe, this annual event has established itself as a premier destination for those at the forefront of sustainable energy solutions.

Where Can You Find SZJ Automation in RENEO 2024?

Against this backdrop of collaboration and exploration, SZJ Automation’s presence at RENEO 2024 holds particular significance. Positioned strategically within Hall D, Booth D17&D20, SZJ Automation aims to unveil four pioneering battery manufacturing turnkey automation solutions, poised to redefine efficiency and scalability in the renewable energy sector.

Introducing Battery Manufacturing Turnkey Automation Solution: What Benefits Can It Bring?

1. What is Battery Manufacturing Turnkey Automation?

Battery manufacturing turnkey automation encompasses a comprehensive suite of automated processes and technologies deployed throughout the battery production lifecycle, from the fabrication of individual cells to the assembly of complete battery packs. At its core, battery manufacturing turnkey automation involves the deployment of sophisticated robotic systems, advanced machinery, and intelligent software solutions to handle tasks that were traditionally performed manually.

2. What Benefits Battery Manufacturers Can Get from Turnkey Battery Manufacturing?

Enhance Operational Efficiency: By automating repetitive and labor-intensive tasks such as material handling, cell assembly, electrode coating, and quality control inspections, manufacturers can achieve higher production rates and throughput while minimizing human error and variability.

Quality and Reliability Promise: Battery manufacturing automated systems can execute precise measurements, perform intricate assembly tasks, and conduct rigorous quality control checks with unparalleled accuracy and repeatability. This level of precision helps mitigate the risk of defects and inconsistencies, thereby elevating the overall quality standards of the manufactured batteries.

Cost-Saving Opportunities: By reducing dependency on manual labor, streamlining workflows, and minimizing material waste, automation helps drive down production costs and enhance cost competitiveness. Furthermore, battery manufacturing automation machines enable manufacturers to achieve economies of scale more effectively, optimizing their operations and maximizing profitability in a rapidly evolving market landscape.

How Many Products You Can Observe on the Stage of SZJ Automation?

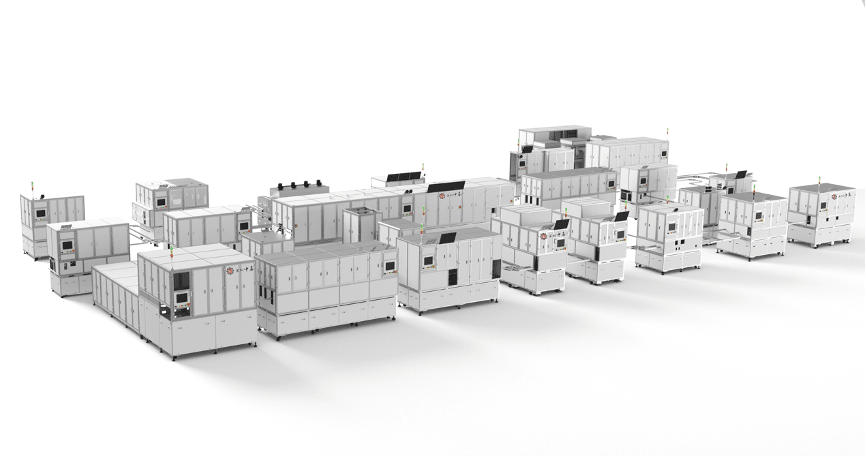

At RENEO 2024, SZJ Automation, a pioneering leader in automation solutions for battery manufacturing, is poised to showcase 4 groundbreaking turnkey automation solutions designed to revolutionize the production of batteries. These innovative solutions are meticulously offering a holistic approach to maximizing productivity, enhancing production efficiency, and ensuring uncompromising quality across the entire manufacturing process. Let’s see what you can get from them.

- Intelligent Solutions for Cylindrical Cell Assembly Line

SZJ Automation’s intelligent solution for cylindrical cell assembly line for lithium/sodium large and small cylindrical batteries represents a paradigm shift in battery assembly technology. With the capability to achieve production rates ranging from 50 to 350 parts per minute (PM), this battery manufacturing turnkey solution sets a new standard for efficiency and productivity in battery manufacturing. Leveraging cutting-edge robotics, precision engineering, and advanced control algorithms, SZJ Automation’s battery manufacturing solution ensures seamless integration of cylindrical cells into battery packs with unparalleled speed and accuracy. Moreover, their dedicated R&D team stands ready in the RENEO 2024 venue, helping you experience this flexible, low-energy consumption, and smart factory development solutions that meet their specific needs and objectives.

- Intelligent Solution for Pouch Cell Assembly Line

SZJ Automation’s intelligent solution for pouch cell assembly line sets a new benchmark for efficiency, quality, and reliability in RENEO 2024 and in pouch battery manufacturing. With the capacity to achieve production rates ranging from 10 to 24 parts per minute (PPM), this innovative turnkey battery line is engineered to meet the demands of high-volume manufacturing while ensuring exceptional product quality. Boasting a remarkable 99% qualification rate for the entire product and an impressive 98% equipment utility rate, SZJ Automation’s pouch battery manufacturing solution delivers unparalleled levels of performance and consistency.

- Intelligent Solution for Prismatic Cell Assembly Line

At RENEO 2024, SZJ Automation will bring intelligent manufacturing turnkey solutions for prismatic cell assembly lines, delivering accuracy and performance for battery manufacturers in need of prismatic battery manufacturing. Their solutions ensure a steady production efficiency ranging from 6 to 24 parts per minute (PPM) for prismatic battery equipment, catering to diverse production requirements with precision and reliability. Furthermore, SZJ Automation’s innovative approach extends to prismatic and blade cell equipment, where they have developed cutting-edge continuous laser welding technology for the top cover edge. This proprietary technology represents a significant advancement over conventional segmental welding methods, increasing efficiency by more than 3 to 5 times, resulting in superior quality and reliability of prismatic battery manufacturing.

- Intelligent Solution for Photovoltaic Cell Production Line

Solar energy is the future. And SZJ Automation is glad to take the photovoltaic cell production line to RENEO 2024, which will open visitors’ minds to cell production. This turnkey automation solution covers 3 pivotal links in the photovoltaic industry chain: silicon wafers, batteries, and modules. By providing a holistic approach to photovoltaic cell production, SZJ Automation empowers manufacturers to streamline operations, reduce costs, and accelerate time-to-market, driving innovation and growth in the dynamic and rapidly expanding field of solar energy.

Conclusion

RENEO 2024 presents a platform showcasing cutting-edge advancements in renewable energy and battery technology, with SZJ Automation at the forefront of innovation. At Hall D, Booth D17&D20, SZJ Automation will unveil four groundbreaking turnkey automation solutions with their over 20 years of experience. They revolutionize battery manufacturing from intelligent solutions for cylindrical, pouch, and prismatic cell assembly lines to comprehensive photovoltaic cell production lines. If you are a battery manufacturer who wants to find a reliable and efficient battery manufacturing solution, just contact SZJ Automation, and come to RENEO 2024 to find them!