Hydraulic presses are widely used in modern manufacturing for their ability to mold materials, shape components, and assemble finished parts with precision. Among the many industries that use this technology, the automotive sector is particularly notable due to its high production volumes, strict accuracy requirements, and complex engineering demands.

Then, what is a hydraulic press in the automotive industry, and how does it help manufacture automotive components? This article will guide you through all the basics and help you find the right hydraulic press machine for automotive applications!

Basics of a Hydraulic Press Machine

1. What is a Hydraulic Press Machine?

Simply put, a hydraulic press is a machine that transforms hydraulic energy into mechanical force by pushing a piston within a sealed cylinder. The principle behind it is based on Pascal’s Law, which states that pressure exerted on a confined fluid is distributed evenly in every direction within that liquid.

2. How does a Hydraulic Press Work?

In a hydraulic press, mechanical energy (from a manual or motor-driven pump) is used to apply pressure to an incompressible fluid inside a closed system. This pressure acts on the piston within the hydraulic cylinder, producing a force proportional to the piston’s surface area. As a result, a relatively small input force can be amplified to generate a very large output force.

3. Components of a Hydraulic Press

The main components of a hydraulic press typically include a pump (manual or electric), one or more hydraulic cylinders containing pistons, a ram or pressing head connected to the piston rod, and a control mechanism to regulate pressure and movement. When fluid is pumped into the cylinder, pressure builds up, and the ram moves downward to apply a controlled compressive force on the workpiece.

4. Types of Hydraulic Press Machines

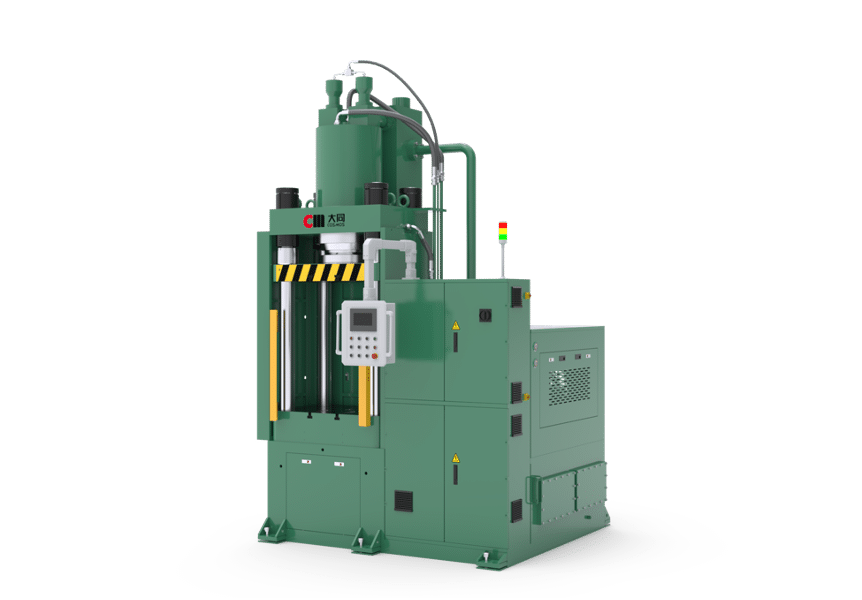

Hydraulic presses come in various frame designs, such as H-frame, C-frame, and four-column configurations. They have their respective features and are ideal for different scenarios.

For instance, four-column presses are known for their structural stability and are commonly used for heavy-duty applications, while C-frame presses offer easier access for smaller or more intricate workpieces. The choice depends on the specific application and operational requirements.

Picture shown: Four Column Cold Extrusion Servo Driven Hydraulic Press

Applications of Hydraulic Presses in Automotive Manufacturing

Now that you know what a hydraulic press is and how it works, here are its top applications in the automotive sector:

1. Shaping and Forming Metal Components

Vehicle frames, panels, and structural reinforcements mostly begin as flat sheets of metal. Hydraulic presses apply controlled force to transform these sheets into precise, three-dimensional parts through processes like deep drawing, bending, and stamping. This allows manufacturers to produce doors, hoods, chassis components, and other essential parts with consistent accuracy and minimal material waste.

2. Assembly Operations

In addition to forming, hydraulic presses are used to fit components such as bushings, bearings, and suspension parts into place. The machines deliver exact pressure levels that ensure tight, damage-free installations. Their role is especially important in electric vehicle manufacturing, where battery packs, enclosures, and other high-tolerance assemblies require careful force application without compromising safety or performance.

Advantages of Using Hydraulic Presses in Automotive Manufacturing

The hydraulic press comes with numerous benefits, such as:

1. High Force Generation

Hydraulic presses are capable of producing extremely high levels of pressure, which allows them to handle heavy-duty forming tasks that involve strong or thick materials. This force is applied evenly, which ensures stable and repeatable performance across large production runs.

2. Precision and Accuracy

With adjustable pressure settings and smooth operation, these machines deliver reliable accuracy for each cycle. This precision level is essential in automotive applications, where small dimensional errors can impact assembly fit or part performance.

3. Versatility

A hydraulic press can be adapted to perform various tasks by simply changing the tooling. From forming and punching to trimming and pressing, the same machine can support multiple stages of production without requiring major modifications.

4. Efficiency and Speed

Modern hydraulic presses are equipped with programmable controls and automation-ready systems that increase production speed while minimizing manual intervention. Short cycle times and consistent output help manufacturers meet high-volume targets without sacrificing quality.

5. Safety Features

Features such as pressure monitors, emergency stop systems, two-hand control mechanisms, and guarded work zones make modern-day hydraulic presses safe and secure. These safety features reduce the risk of operator injury and support compliance with workplace safety standards.

How to Choose Hydraulic Press Machines for Automotive Applications

Once you want to invest in a hydraulic press machine, here are some top factors to consider:

1. Understand Production Needs

Before choosing a press, it’s essential to define the scope of work. This includes identifying the types of materials being processed, the specific design requirements of the automotive parts, and the required production volume. So, explore the different types of hydraulic press machines and their specific use cases before finalizing the equipment.

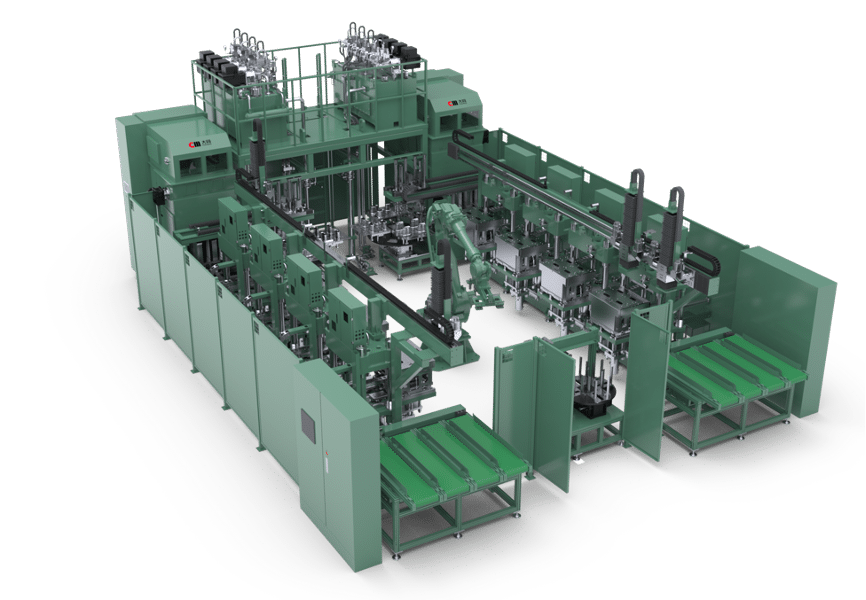

Picture shown: Brake Pad Hot Pressing Automatic Production Line

2. Evaluate the Key Features of a Hydraulic Press

Once the requirements are clear, attention should turn to the specific capabilities of the hydraulic press. Tonnage capacity must align with the material strength and forming demands. Press speed, stroke length, and control systems affect both efficiency and output quality. Additional factors like automation compatibility, energy consumption, noise level, ease of maintenance, and built-in safety systems should also be considered.

3. Cost Considerations

While the initial purchase price is important, it should not be the only factor that guides your decision. A well-built machine that runs efficiently and requires minimal downtime will offer better value over time. Total cost of ownership should account for energy use, tooling requirements, service needs, and any potential production losses due to breakdowns or slow changeovers.

4. After-Sale Services

Strong technical support and responsive service are critical in a fast-paced manufacturing environment. Suppliers who offer training, routine maintenance packages, quick access to spare parts, and remote diagnostics provide added value and peace of mind. A good after-sales program helps ensure continuous performance and reduces the risk of unexpected disruptions.

Work with a Reliable Hydraulic Press Manufacturer!

If you are looking for high-performance hydraulic press machines, Cosmos Press can be a reliable hydraulic press manufacturer to cooperate with.

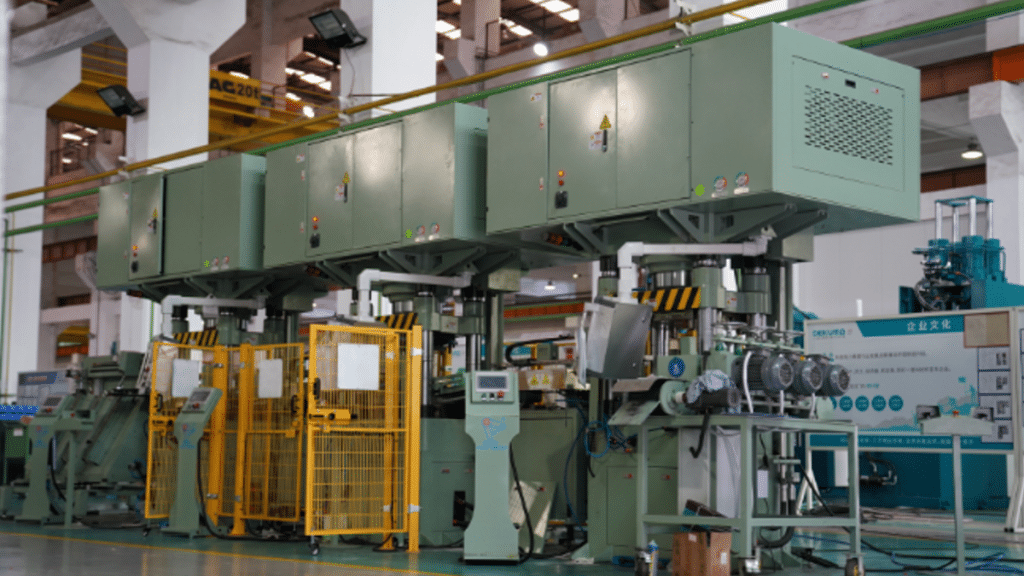

This hydraulic press brand offers different types of hydraulic press machines, available in capacities from 1 to 5000 tons. Their models include C-frame presses, four-column up-stroke presses, frame-type systems, and double-action servo-driven machines. Many of them are designed specifically for automotive applications like brake pads and steering shaft production.

With over 45 years of experience in the industry, Cosmos Press continuously advances its technology, allowing it to produce hydraulic presses renowned for their high precision, stability, and efficiency. Furthermore, their hydraulic press machines are ISO- and CE-certified.

Wrapping Up

What is a hydraulic press for automotive applications? It is a tool vital to modern automotive manufacturing, offering the force, accuracy, and efficiency needed for high-volume and high-precision production.

Cosmos Press stands out with its proven experience, advanced technology, and ISO-certified quality. For manufacturers looking for reliable, high-performance hydraulic press solutions, Cosmos Press is a trusted partner worth exploring.

If you are interested, click here to contact them for more!